Drop shafts and vent shafts provide access or ventilation into a large-diameter, horizontally bored tunnel through bedrock.

Common uses

Process

The most common types of these shafts and tunnels are part of Combined Sewer Overflow (CSO) projects, where untreated or partially treated waste, debris, and stormwater are collected and stored during large weather events that would otherwise lead to flooding.

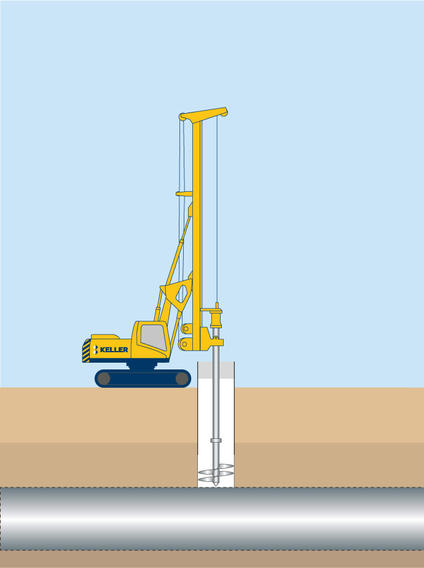

Using specialized drilling equipment, Keller excavates overburden and sets a permanent steel casing on the underground bedrock layer. This casing is often grouted in place. Then, the rock is removed below it to a specified elevation, usually coinciding with the top of the tunnel to be bored below it.

For larger-diameter drop shafts exceeding 12 feet in diameter, a secant pile wall can be constructed to support the excavation instead.

Specialist contact

- T:

- 973-400-3631

Paul is responsible for the strategic pursuit of new underground construction work largely in tunneling, dam construction and rehabilitation, and CCR stabilization. Previously Senior Vice President and Chief Engineer of Moretrench American Corporation, a nationally renowned specialty geotechnical contractor. Responsible for the technical oversight of the company’s soil stabilization, grouting, ground freezing, groundwater control and environmental remediation. Extensive experience with emergency response for geotechnical “failures” related to groundwater and forensic investigation of deep excavation and tunneling ground loss events. Co-author of the third edition of Construction Dewatering and Groundwater Control, published in 2007.