During construction, it is often necessary to form a stable excavation to ensure that any associated movement will not damage neighboring structures or utilities. Keller offers flexible solutions to solve even highly complex temporary support of excavation or permanent support of excavation problems.

Common Uses

- Support excavations/excavation bracing

- Shore existing adjacent structures

- Laterally support placed fills

- Bulkhead/wharf support and remediation

The design and construction of support of excavation (SOE) systems can be complex due to the soil structure, depth of cut and groundwater, weather conditions, superimposed loads, seismic loads, vibrations, and adjacent construction. The design must address the stability of the excavation bottom when below the water table.

Buildings, construction equipment, and stockpiled materials adjacent to an excavation result in lateral loads on the retention system. The underpinning of adjacent structures can reduce the loading on an excavation wall and the risk of building settlement. Excavation shoring can be affected by vibrations from traffic, railways, blasting, and machines operated in adjacent buildings.

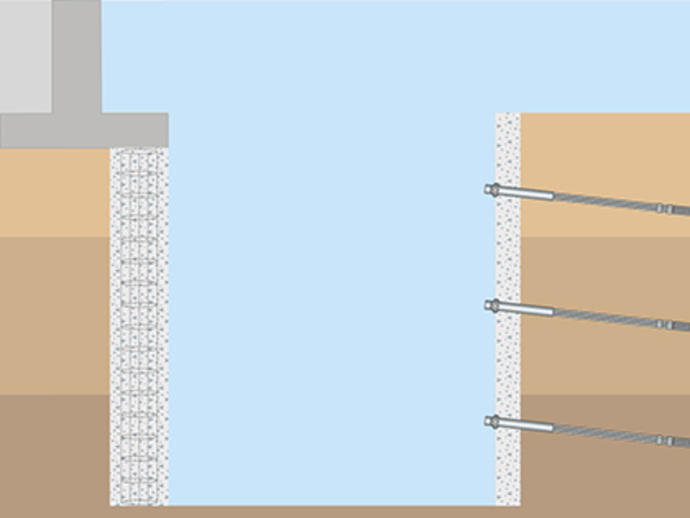

Common permanent and temporary excavation shoring systems include steel sheet piling, soldier piles and lagging, jet or chemical grouting, secant or tangent piles, and soil nail walls. Anchors or bracing can provide lateral support for sheeting and shoring systems. Access shafts for tunneling and trenchless construction may involve a circular shoring system designed as a compression ring. Construction shoring for excavations that are open for extended periods may require protection from weather conditions.

Extreme caution must be used during shoring excavation, and safety is paramount. We understand the hazards associated with earth shoring and the importance of trench safety. We have experience with the full range of techniques to provide reliable support of excavation design and installation.