Mixed modulus columns (columns with Mixed Moduli, mixed columns, or CMM®) is a ground improvement method using high deformation modulus columns constructed through compressible soils to reduce settlement and increase bearing capacity. CMM® is the combination of a rigid inclusion for its lower part with a ‘supple’ inclusion in compacted gravel or crushed stone for the upper part.

Common uses

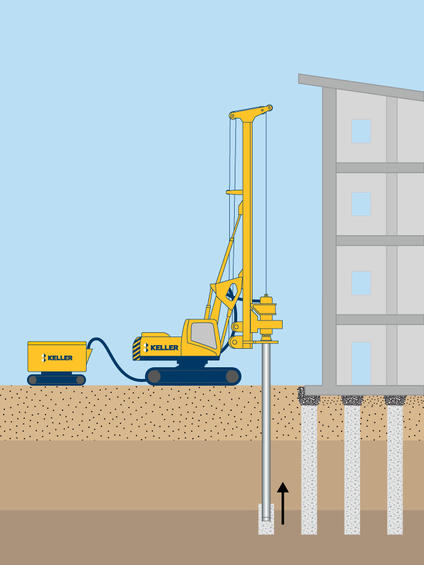

Process

After the working platform is prepared, the rig is placed, and data recording starts. Generally, a displacement auger or vibrated tube penetrates down to the designed depth. Concrete is pumped as the tool is pulled upwards. Once the rigid inclusion is installed up to the designed level, a column of gravel or crushed stone, horizontally displaced, is installed on top. Its length is adapted to the characteristics of the project (bottom level of the shallow foundations, rafts, and slabs; stratigraphy of the soil). Typically it is between 1.0 and 1.5m, even though it can be contemplated to install it deeper.

Advantages

Quality assurance

Mixed columns are controlled before, during, and after installation to ensure the highest quality solution. A variety of tests can be carried out, including:

- Field trials for verifying columns production parameters

- Digital recording and logging of the execution parameters

- Column load test, column material compressive strength tests, column diameter verification

The type and frequency of tests vary based on the size of the project and the geotechnical context.