Micropiles (mini piles, pin piles, needle piles, and root piles) are deep foundation elements constructed using high-strength, small-diameter steel casing and/or threaded bars.

Common uses

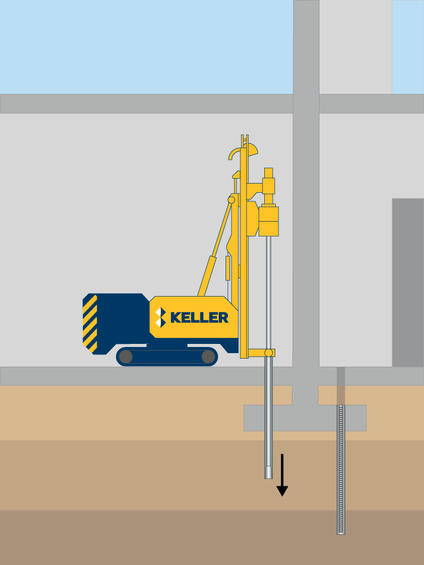

Process

The micropile casing generally has a diameter in the range of 3 to 10 inches. Typically, the casing is advanced to the design depth using a drilling technique. Reinforcing steel, typically an all-thread bar is inserted into the casing. High-strength cement grout is then pumped into the casing. The casing may extend to the full depth or end above the bond zone, with the reinforcing bar extending to the full depth.

This technique has been used to support most types of structures. Keller’s micropile drill rigs allow installation in restricted access and low-headroom interiors, allowing facility upgrades with minimal disruption to normal operations.

Keller can combine our micropile technology with one or more of our other ground modification techniques to meet unique or complex project requirements cost-effectively and efficiently. Lines of micropiles spanned by wooden lagging can be ideal where excavation walls are required in low headroom and other confined areas. Post-grouting within the bond length can increase frictional forces with surrounding soils and achieve greater capacity. Micropiles can serve to “stitch” the soil together within predicted shear zones to enhance mass stability. In liquefiable profiles, micropiles can transfer loads to competent bearing strata to follow seismic design requirements.

Advantages

Quality assurance

The finished micropile (mini pile) resists compressive, uplift/tension, and lateral loads and is typically load tested following ASTM D 1143 (compressive), ASTM D 3689 (uplift/tension), and ASTM D 3966 (lateral). Capacities vary depending on the micropile size and subsurface profile. Allowable compressive capacities of more than 500 tons have been achieved.