The earthquake drain ground improvement method minimizes bearing capacity failures and settlement during and immediately after a seismic event. It mitigates liquefaction by limiting excess pore pressures generated during seismic events to levels less than those that could trigger liquefaction.

Common uses

Process

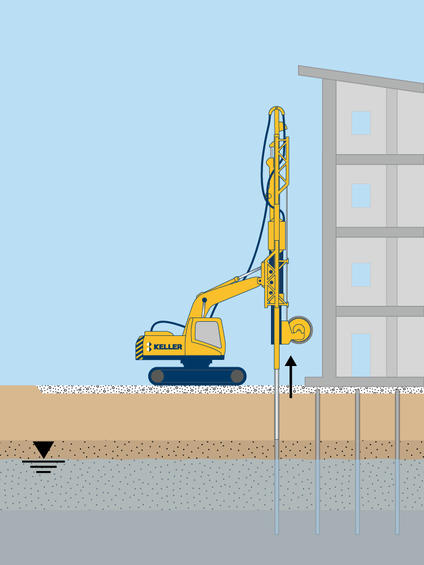

Earthquake drains are installed by vibrating the insertion mandrel during penetration and removal. Typically, the insertion mandrel consists of a heavy-gauge steel pipe with three equally spaced fins to transfer vibrations to the adjacent soil. The vibrations result in some densification of the granular soils, assisting in the liquefaction mitigation.

The nominal 75mm (3 inches) diameter drain core is tightly wrapped with geotextile filter fabric (selected for its filtration properties), allowing free access of pore water into the drain while preventing the piping of fines from adjacent soils. The geotextile wrap is durable and can withstand handling and abrasion during installation. Several core designs and fabric types can be used to fit a variety of drainage applications and soil classifications.

Liquefaction mitigation achieved with earthquake drains can be valuable for support of embankments, reduction of lateral spreading from seismic loading, containment of densified ground, support of floor slabs in certain conditions, liquefaction mitigation of mine tailings, and reducing seismic deformations of pile groups. Combined with other ground improvement techniques, earthquake drains can be applied to big box stores, mid-rise buildings, tanks, ports, and hydraulic fills.

Advantages

Quality assurance

Keller is highly experienced in designing and constructing this technique and has designed and installed millions of meters of earthquake drains.