CFA / ACIP piles (continuous flight auger piles, auger cast piles, or augered cast-in-place piles) are cast-in-place piles using a hollow stem auger with continuous flights.

Common uses

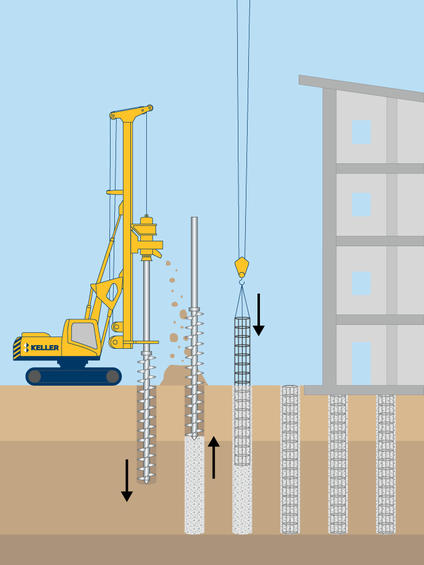

Process

CFA / ACIP piles are constructed by rotating a hollow stem continuous flight auger into the soil to a designed depth. Concrete or grout is pumped through the hollow stem, maintaining static head pressure, to fill the cylindrical cavity created as the auger is slowly removed. The grout pressure and volume must be carefully controlled to construct a continuous pile without defects. The reinforcement cage is placed through the freshly placed concrete.

Typically, Keller CFA / ACIP piles are reinforced with a rigid six-meter-long cage as a minimum, but it’s possible to install much longer cages as and when required by the design or specification. If required, a specially developed vibrator unit can help accurately locate the reinforcement cages.

Advantages

Quality assurance

Close control of the installation process is essential to ensure the highest quality pile construction. All Keller CFA / ACIP rigs are equipped with sensitive state-of-the-art instrumentation that monitors all aspects of CFA /ACIP piling, including pile depth, auger rotation, penetration rate, concreting pressure, extraction rate, and over-break. The instrumentation produces an individual log for each pile, including element identification, date, time, and operator details.

A documented Quality Management System procedure reinforces this. Quality assurance is achieved through various non-destructive testing methods to evaluate pile integrity and load-settlement performance. The selection of verification techniques is project and application specific.