Environmental remediation encompasses a broad spectrum of services, multiple techniques, and markets. It includes removing or containing hazardous waste or subsurface contaminants produced by or located at coal power plants, mines, and former or operational industrial or manufacturing sites.

Keller is a recognized environmental remediation leader. Projects have been completed under RCRA, CERCLA, and TSCA regulations and with agencies such as the EPA, FERC, USACE, and hundreds of state and local entities.

We have the expertise and resources you need for a single solution or an integrated package.

Common Uses

- Treatment of contaminated water

- Prevent migration of contaminants

- Waste encapsulation/solidification

- Brownfields and industrial property redevelopment

- Mine tailings consolidation

Keller has successfully designed and implemented geotechnical solutions tailored to site-specific conditions for tailings storage, acid mine drainage, landfills, brownfield sites, and Coal Combustion Residuals (CCR). Methods include barrier/cutoff walls, in situ stabilization, various geostructural and support of excavation techniques, and dewatering and water treatment/pump and treat systems.

Coal Combustion Residuals (CCR)

The recent “CCR rule” requires the closure of all fly ash ponds by excavation and removal, regrading and capping, or a combination of a “hybrid” closure approach.

Keller has worked on over 30 ash pond closure projects and understands that the properties and behaviors of fly ash are highly problematic and known to be unstable and sensitive to vibration when saturated. This can make excavation, handling, and disposal of this material challenging.

Keller uses various techniques at these facilities, including:

- Dewatering of ash

- Treatment of ash pore water

- Soil mixing and grouting methods for geostructural improvements in ash

- Environmental barrier/cutoff walls at the site perimeter

- Instrumentation and monitoring programs for construction safety and permanent site features

- Anchors, sheet piles, soldier piles and lagging for earth retention in ash

Each site is unique, and we have the expertise and resources you need for a single solution or an integrated package.

Mine tailings and waste

Challenges associated with the disposal and containment of mine tailings and waste can be addressed by solutions such as:

- Wick drains for tailings consolidation

- Seismic stabilization of perimeter embankments and dikes

- Cutoff walls for groundwater control and contaminant migration

- Water treatment

- Drainage and dewatering of tailings

Cleanup of contaminated sites

Keller can help with redevelopment efforts of brownfields or landfills using geotechnical methods such as soil mixing, jet grouting, slurry walls, and water treatment systems.

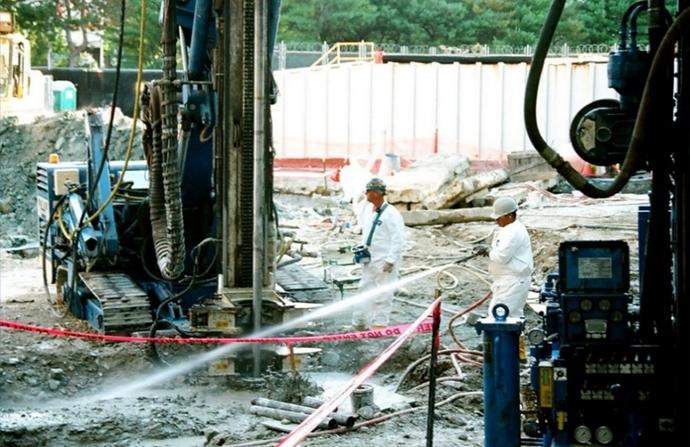

Excavation and removal still represent a leading method of remediating contaminated sites. Keller performs highly surgical and mass removal of impacted media, including soils, sediments, and chemical residuals. Moretrench Industrial, a Keller company, has specialty earthwork capabilities in materials other than typical soil. Many of our projects include a shoring system to ensure safety. Additional methods safely remove contamination adjacent to buildings, under power lines, and near active plant operations.

Stabilization can reduce the mobility of hazardous substances and contaminants in the environment through physical and chemical means. We use a unique blend of reagents to trap or immobilize contaminants within the contaminated soil or sludge.

Slurry trench groundwater barriers

Subsurface slurry trenches are installed using various equipment, including hydraulic / long-reach excavators, hydraulic and mechanical clams, trenching machines, and custom buckets. These cutoff walls can consist of soil-bentonite, soil-cement-bentonite, soil attapulgite, soil cement and attapulgite, cement bentonite, and concrete.

Passive groundwater treatment systems

Passive treatment systems permit groundwater to flow through specific treatment media. Groundwater contaminants react with the installed treatment medium and are degraded, precipitated, or absorbed in situ, depending on the contaminant type and treatment system.

Passive treatment systems use naturally occurring environmental processes, chemical and biological, to cleanse contaminated waters. Some passive treatment systems we maintain include iron filing walls, funnel and gate systems, passive biotrenches, permeable reactive barrier walls, and built-in filtration systems.

Groundwater recovery and treatment

Recovery treatment systems remove contaminants in groundwater, such as solvents, metals, fuel oils, or other regulated substances. Groundwater is pumped to an above-ground treatment system from extraction wells within the polluted groundwater plume. Some of the treatment system components then address contaminants using the following methods.

- Soil vapor extraction

- Oil-water separators

- Air stripping towers

- Granular activated carbon

- Thermal oxidizers

- Pumping systems

Soil treatment

Soil can be treated in place with the mechanical blending of the natural soil and a binder to encapsulate constituents of concern. This is typically done with soil mixing techniques and is referred to as In Situ Stabilization (ISS).

Various reagents and reducers stabilize or oxidize contaminated soil, including triple superphosphate, buffering agents, cement, potassium permanganate, hydrogen peroxide, sodium percarbonate ZVI, and ferric sulfate. Each technique requires a mechanical mechanism to complete the treatment, using deep soil mixing rigs and traditional construction equipment to introduce the reagents.

Bioremediation projects are completed using in situ and ex situ techniques. In situ bioremediation, or bioventing, involves stimulating indigenous microbial populations in the subsurface to biodegrade organic contaminants. Ex situ techniques, including windrowing, are coupled with added nutrients to enhance the remediated treatment of the media.