The Virginia Port Authority seeks to increase its East Coast market share of container storage and distribution by taking advantage of Portsmouth’s deep water and prime distribution position to create a 500+-acre area of above-water “made land” stretching out into the Elizabeth River.

The project

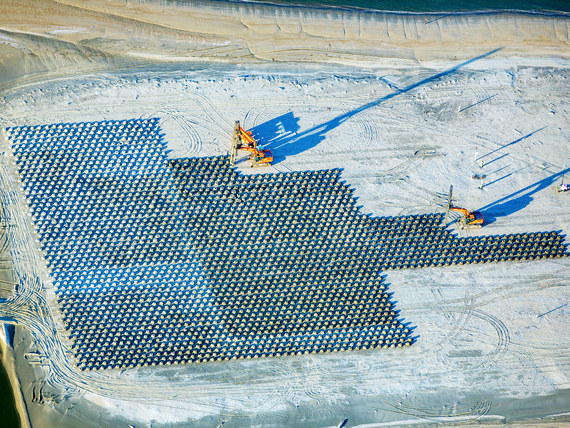

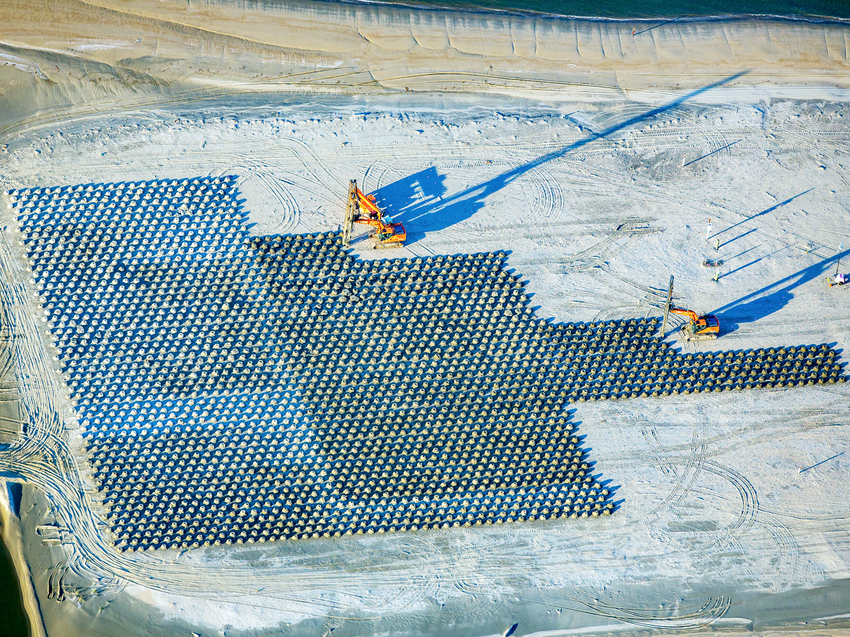

When completed, the area will allow the Virginia Port Authority to double its container-handling capacity through the creation of an additional marine terminal. The project which is being let in phases over time is a joint venture between the Virginia Port Authority and the US Army Corps of Engineers (USACE), which owns the Craney Island Dredged Material Management Area (CIDMMA) on which the new marine terminal will be created. The most recent phase of the project, completed in 2018, involved the remediation of 20 acres of under-consolidated riverbed sediment to a depth of 140 ft at the site. Several options were initially considered to achieve the remediation, but ultimately, wick drains were selected based on the time and cost consideration this technique offered. Keller was awarded the prime contract for the wick drain installation.

The challenge

The thick deposit of under-consolidated riverbed settlement was expected to exhibit as much as 20 ft of settlement under the surcharge. Furthermore, the work needed to be completed within a specified timeframe that included hurricane season and also stretched over the winter months. The crew faced several tropical storms and also was required to stand down during nesting season of the Piping Plover, a protected bird. These unavoidable delays meant that time became of the essence.

The solution

The wick material as specified had to filter the fine grains of the sediment as well as maintain functionality as the deep thickness of soft soil continued to settle and deform the wicks. Since no American-made wick satisfied the criteria, components were identified for their robust quality and high-flow filter properties and were thicker and stronger than typical wick drain material. Keller, which customarily manufactures the wicks it uses in-house, modified its equipment to effectively manufacture the new material and also custom-built a site-specific installation unit for insertion of the drains.

Wicks were installed on a 5-ft triangular pattern across the 20-acre site. The installation unit was fitted with a data acquisition system to record installation details for each wick and verify that installation parameters were met. More than 4,000 wick drains were installed to a depth of 140 ft for the project, involving over 5,000,000 LF of wick material.

The completed project resulted in significant time savings over that which would be required for consolidation and drainage over such a large area to occur naturally.