For this project, Keller designed a ground freezing system that was wholly installed within the tunnels – the first-of-its-kind application in North America.

The project

The Northgate Link Extension extends Sound Transit’s Link light rail system from the existing northern terminus at the University of Washington’s Husky Stadium to Northgate Station. The twin-bore tunnels are connected by 23 cross passages, spaced approximately every 800ft, that provide emergency egress and house mechanical and electrical equipment. Ground improvement (dewatering, jet grouting, or ground freezing) was specified prior to cross passage excavation by the sequential excavation method (SEM).

The challenge

At five consecutive locations where deep wells installed from street level were planned (CP-34 through CP-38), pump test analyses showed that the soils were more permeable than expected. Given the operating period required, the anticipated volume of water to be disposed of, discharge costs, and potential overload of the sewer system, this solution was deemed infeasible. At one location where surface access restrictions precluded vertical drilling (CP-23), vacuum well dewatering was planned to be accomplished from within the tunnel itself. However, pre-probing revealed that rapidly flowing fine-grained soils rendered dewatering infeasible here also. Keller was approached by the main contractor for the tunneling work to develop a viable ground freezing solution in lieu of dewatering.

The solution

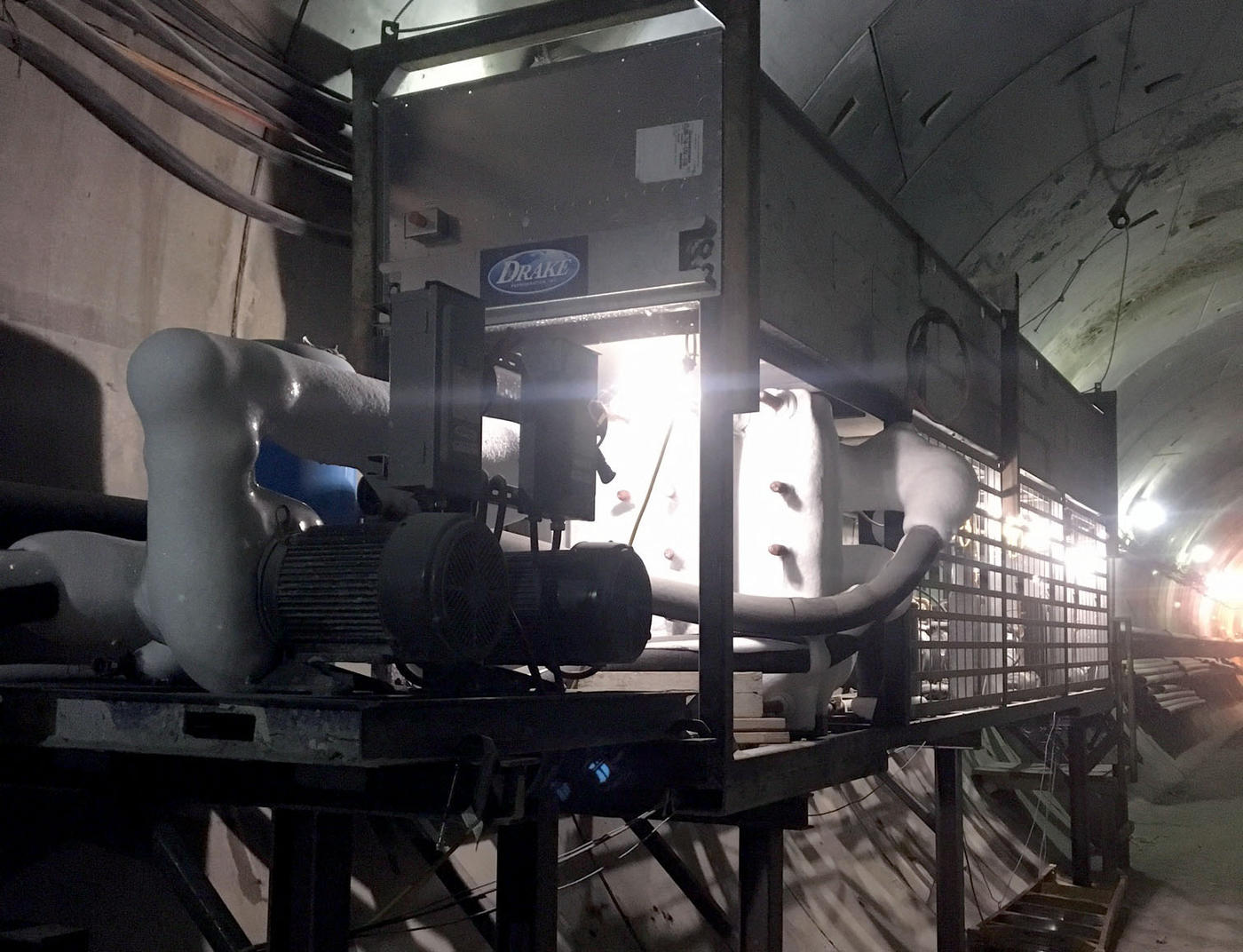

Due to surface restrictions, horizontal ground freezing was an attractive option. However, the six cross passages were located too far from the tunnel entrance to consider setting up the mobile freeze plant there. In a first-of-its-kind application in North America, Keller, therefore, designed the ground freezing system, including the freezing plant, to be wholly installed from within the TBM tunnels. Custom skid-mounted plants were mounted to the sides of the tunnel liner, allowing unimpeded access for tunneling operations during the freeze system operation. Crucially, the smaller compressors required for these plants used Freon as the cooling agent rather than the traditional ammonia which poses a significant health hazard in enclosed environments.

During excavation, all of the cross passages remained dry and stable, with no instances of groundwater seepage or soil raveling. The success of this project demonstrates that this technology is especially applicable in urban environments where surface disruptions are becoming increasingly unpalatable to the public.