Yucca Loma Bridge over the Mojave River was constructed to relieve traffic congestion in Los Angeles. Bridge foundations required drilling through difficult subsurface conditions.

The project

Additional infrastructure is needed to facilitate the daily commutes of the ever-expanding population of the high desert above Riverside and Los Angeles counties. Surface streets in many of these communities became heavily congested during the typical morning and evening rush hours. The Yucca Loma Bridge project is part of the infrastructure improvement needed to relieve the congestion and to more effectively allow the population to access the interstate system. The project includes the construction of a 13-span bridge over the Mojave River. The new bridge is approximately 1,600 feet long from end to end.

The challenge

The project site traverses young, alluvial valley deposits of the fan type in an area of relatively low relief across the Mojave River. The deposits consist of mixtures of silt, clay, sand, pebbles, gravel, and boulders, and are unconsolidated to moderately consolidated and interbedded. The subsurface groundwater is tied to the elevation of the Mojave River, making drilling conditions more difficult.

The solution

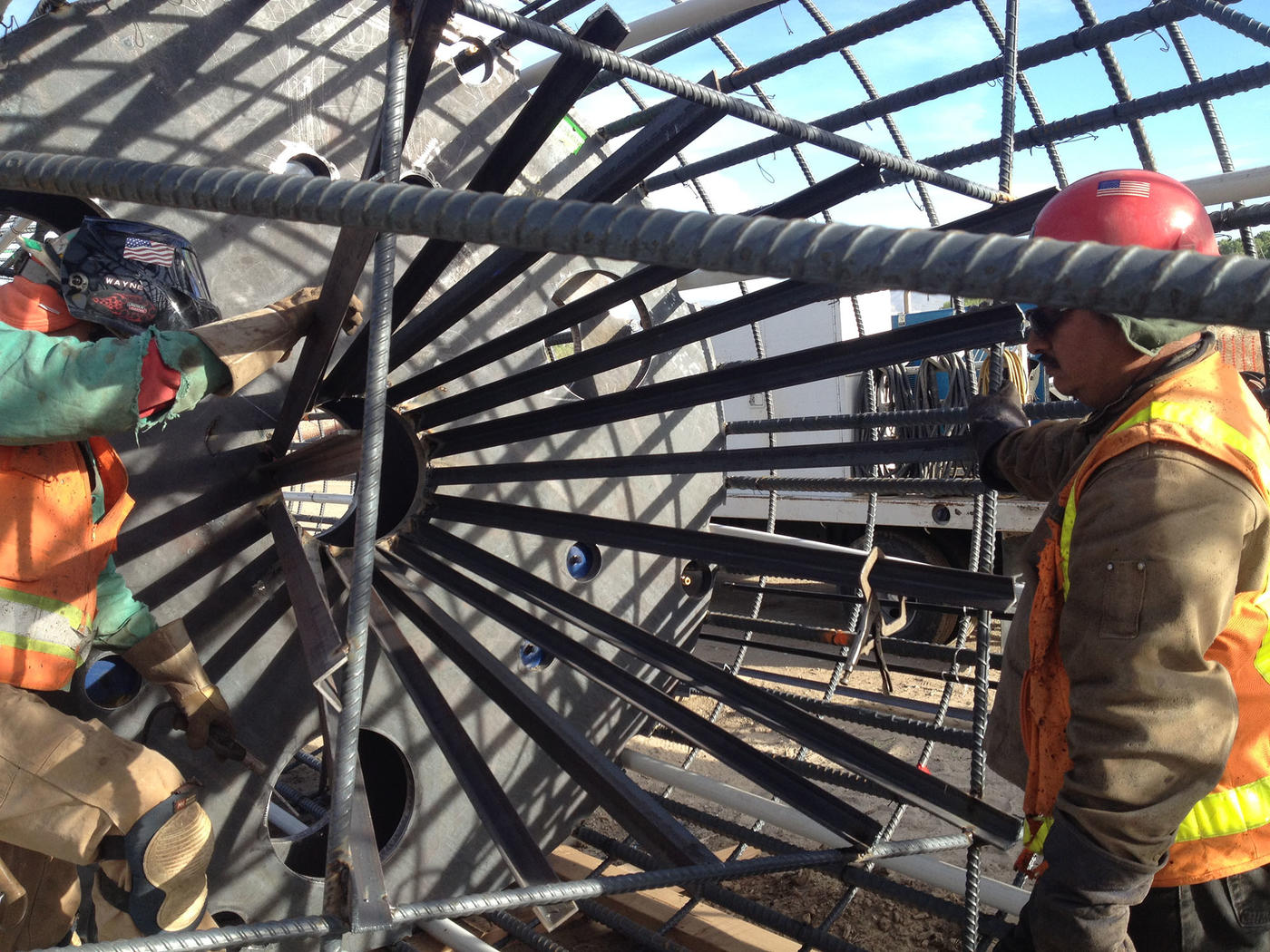

Keller was retained to construct the drilled shaft, also known as Cast-In-Drilled-Hole (CIDH) pile foundation. The abutments of the bridge are supported on each end by 6 each 72-inch-diameter drilled shafts and each of the 12 piers for the bridge is supported on 4 each, 120-inch diameter drilled shafts. The working elevation for the bridge piers was 20 feet above the drilled shaft cut-off elevation, resulting in total drilling depths of 115 feet. Noise barriers for the project were supported by 12-inch-diameter drilled shafts.

Drilled shaft quality control on this project was extensive, including Osterberg Cells (O-Cells), Mini Shaft Inspection Device (Mini SID), Gamma-Gamma Non-Destructive testing techniques, and SoniCaliper.